The Department of Energy’s Argonne National Laboratory has been conducting research with the goal of offering a guide for stakeholders on selecting the biofuel pathways that best meet their needs based on a number of complex variables.

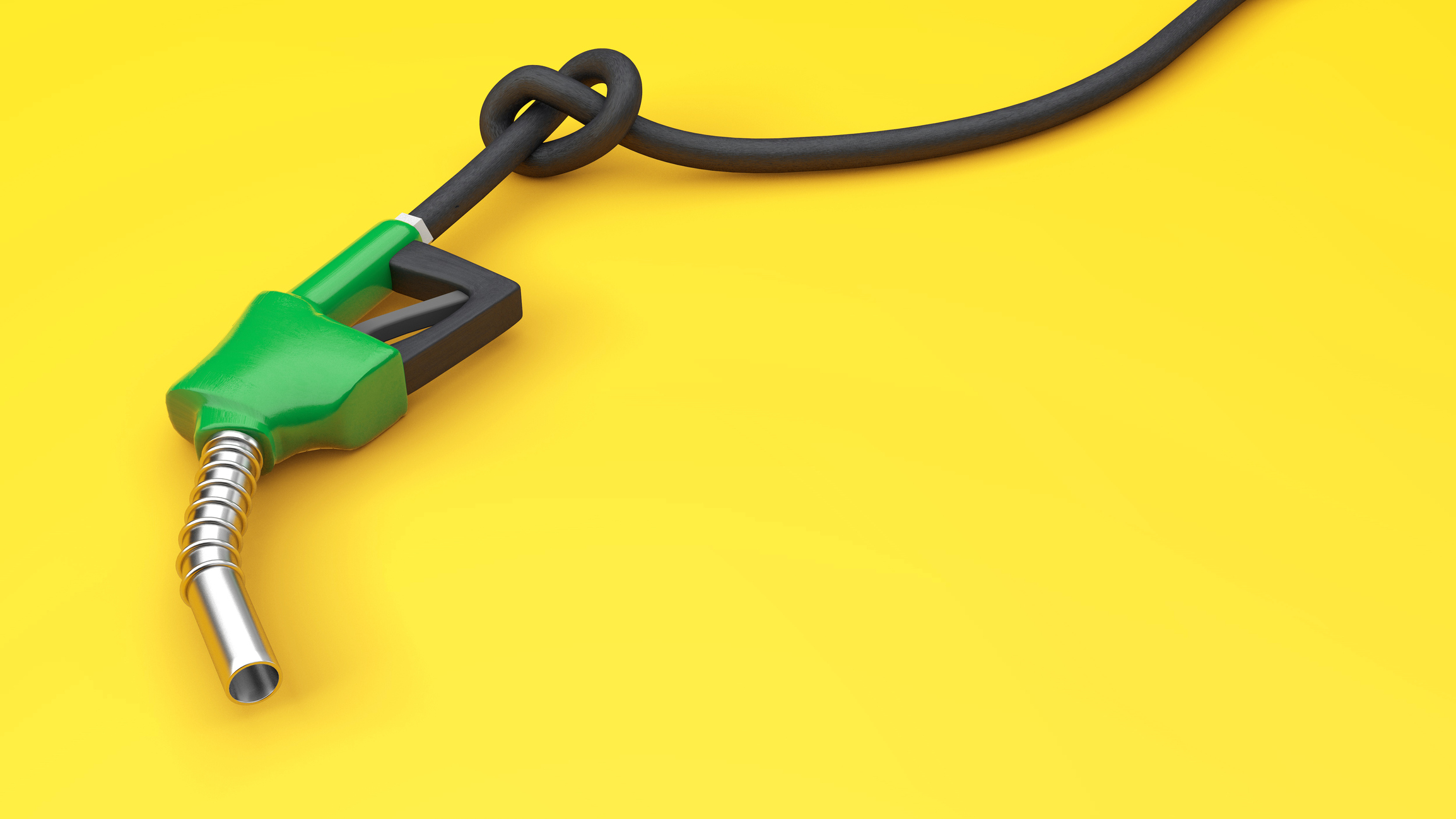

For the trucking industry, the big question is whether it can become cost competitive with traditional fuel, and if it does, when? In this article we’ll look at what makes biofuel potentially attractive to trucking fleets and examine how far away we are from seeing any real change on the road.

According to two new studies, biofuel, combined with advanced engine design, can reduce greenhouse gas emissions of vehicles by as much as 60% while also improving fuel efficiency.

These studies were conducted by Argonne in collaboration with the DOE’s National Renewable Energy Laboratory, Pacific Northwest National Laboratory, and Idaho National Laboratory. Researchers conducting the study considered cost, environmental impact, and potential for expanding to commercial markets to identify promising fuels for different engine types. The research is supported by the Co-Optimization of Fuels & Engines (Co-Optima) initiative jointly led by DOE’s Office of Energy Efficiency and Renewable Energy, Bioenergy Technologies Office, and Vehicle Technologies Office.

Biofuel is produced from biomass – organic materials including plants, agricultural waste, and wet waste. Biofuel can be blended with conventional fuel to reduce emissions and improve fuel and engine performance. Converting biomass to biofuel is a complex process involving variables in feedstock, conversion technologies, and fuel types. It is especially challenging finding biofuel pathways that also meet economic, technology, and energy goals.

In a study co-authored by Benavides, a team assessed 12 biofuel production pathways for optimizing multimode internal combustion engines. Using renewable biomass feedstock found in forestry byproducts and agricultural waste, they used conversion technologies to discover that seven biofuels can be produced cost competitively.

In another study co-authored by Barling, researchers analyzed 25 ways of producing biofuel optimized for a mixing-controlled compression ignition. This type of diesel engine is mainly used in freight transportation. As with the first study, most technologies performed well with most biofuels cost-competitive with current fuel prices.

They key to biofuel success is cost competitiveness. While many of these biofuel pathways could potentially be cost competitive, it’s too soon to lock in prices in a constantly fluctuating gas market.

Biofuels offer a number of benefits to fleets, including:

• Reducing greenhouse gas emissions.

• Reducing dependence on foreign oil.

• Reduce the cost of fuel for trucking fleets by using a domestically produced alternative to diesel or gasoline that can be blended with traditional fuels at a low cost per unit of energy.

If biofuel can produce enough energy that it costs less than petroleum-based fuel, then converting trucks and other vehicles to run on them could be an attractive strategy.

Some companies are already seeing this potential in the market: In 2017, FedEx Express announced plans to convert its entire fleet of trucks to run on B20 (20% biofuel), and UPS has said that by 2025 all of its ground fleet will run on renewable diesel from plants such as algae or jatropha.*

The bottom line is that biofuels can be a cost-effective solution for trucking fleets looking to reduce their fuel costs and emissions. This isn’t just an environmental solution; it could also mean big savings for fleet owners who are looking for ways to keep their costs down without sacrificing quality or performance.